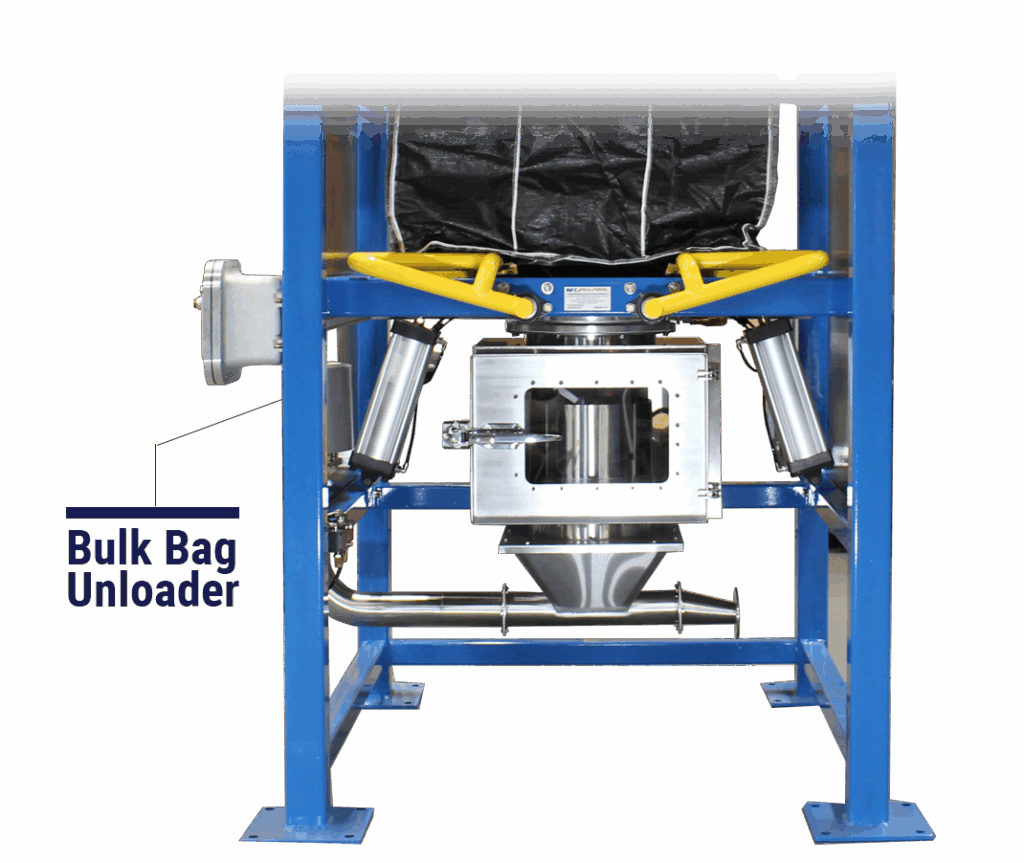

AFC Bulk Bag Unloaders

Superior workmanship, customized for your application

Discharge your FIBCs (bulk bags) safely, efficiently, and dust-free.

AFC bulk bag unloaders safely and automatically discharge powders and other bulk materials from flexible intermediate bulk containers (FIBC), Super Sacks, and other bulk bags for conveying to storage, to day bins, or directly into a process. These bulk bag unloaders are custom designed based on the material properties and other requirements to promote fast, efficient, dust-free operation. Whether discharging free-flowing powders or non-free-flowing, sticky, caking, troublesome materials laden with agglomerated lumps and chunks, our expert engineering and rock-solid manufacturing ensure smooth, consistent unloading bag after bag, year after year.

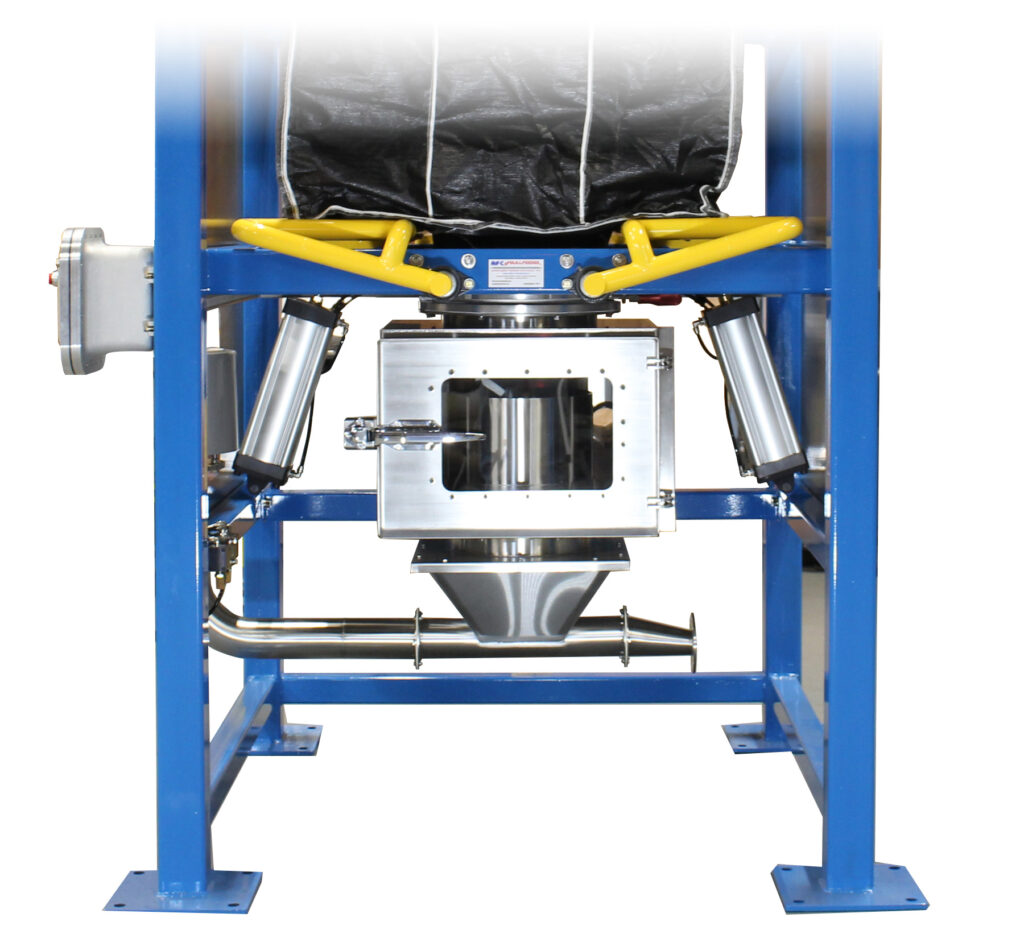

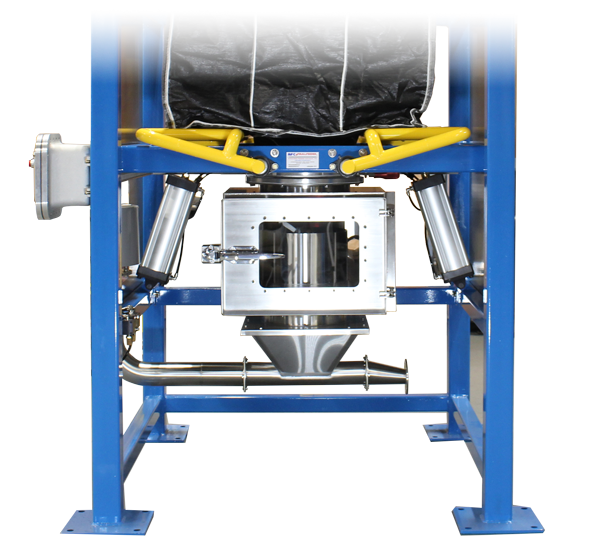

Innovative tie box allows material flow monitoring

AFC engineers offer a proprietary, dust-tight tie box bag spout interface design that features an optional clear window. This allows the operator to see the material discharging from the bag and monitor the flow rate without opening the access housing or risking release of material into the workplace. It’s easy to see that it’s working as planned and easy to quickly address any bridging, blockages, or flow rate fluctuations without losing time, releasing a dust cloud, or putting workers at risk.

Bulk bag unloading options

- Built-in load cell controls provide accurate weighing (LIW) of material unloaded and conveyed to your process

- Automated pneumatic massagers promote discharge of non-free-flowing materials

- Manual Iris valve

- Integrated sifter, lump breaker, conveyor and/or other equipment available

- Mild steel or stainless steel construction: T-304 or T316

- Industrial or sanitary finish

- Low profile units for restricted head room areas

- Bulk discharge half frames

- Hazardous and non-hazardous locations

- FDA, USDA compliant and explosion-proof designs

Sturdy, Secure Steel Construction Made in USA

AFC bulk bag unloading machines feature durable construction in a structural framework that is fully welded for high strength, rigidity and integrity capable of handling filled bags to 4,000 lbs. Integrating both structural steel and tubular steel, these superior machines provide an unsurpassed value in frame work design and quality in manufacturing. AFC engineers design the ideal unloading frame configuration to suit the installation and the proper hole pattern in the frame to accommodate a diverse range of bulk bag height sizes and styles: choose chain hoist unloader with a cantilevered I- beam, forklift unloader, half frame unloader – or a completely custom configuration.

Chain Hoist Style

A single operator advances the chain hoist to the outside of the bulk bag unloader and lowers the hook with the bag lifting device over the top of the bulk bag. The bulk bag loops are then placed onto the bag lifting device hooks. Then the bag is raised and maneuvered into position over the iris valve and lowered on top of the massager paddles while maintaining tension on the bag loops. Next, the access housing/ untie box door is opened and the bulk bag spout is pulled downward through the iris valve and into the access housing. The iris valve is closed and the bulk bag untied. Finally, the door to the access housing is closed and the iris valve is ready to be opened. At the press of a button on the control panel, the bulk bag unloader starts discharging the material.

Forklift Style

A forklift operator lifts and removes the bulk bag lifting device from the top of the bulk bag frame and lowers it to a position over the top of a bulk bag. The bulk bag loops are then placed onto the bag lifting device hooks while engaging the safety latches. The bag is raised and maneuvered into position on top of the unloading frame until the safety stops are reached. Then the access housing/ untie box door is opened and the bulk bag spout pulled downward through the iris valve and into the access housing. The iris valve is then closed and the bulk bag is untied. Finally, the door to the access housing is closed and the iris valve is ready to be opened. At the press of a button on the control panel, the bulk bag unloader starts discharging the material.