Reliably weigh your products with an accuracy of more than 99%.

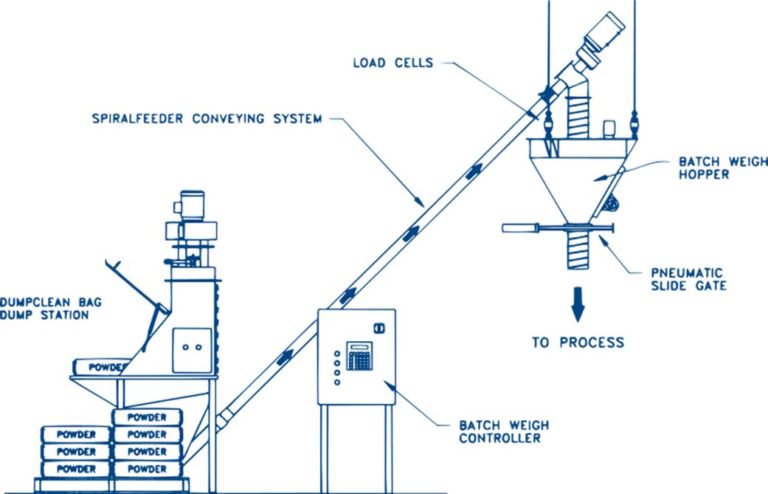

Automated Flexible Conveyor’s new Batch-Weigh System automatically transfers, weighs, and dispenses precise amounts of powders, pellets, flakes, and other bulk materials into mixers, hoppers, tanks, vessels and containers.

The Batch-Weigh consists of a receiving hopper with hopper slide gate to contain the batch quantity, load cells, and control panel. The controls incorporate the latest electronic technology in AC Inverter drives and Programmable Logic Controllers (PLC’s). Settings and adjustments are easily done at the push of a button on the front mounted keypad through a simple, menu-oriented LCD display. Batch-Weigh may be custom-configured to suit any operating environment, including explosion hazard areas.

What is it

The Automated Flexible Conveyor batch weigh System is an integrated weighing system that can weigh single or multiple ingredient(s) from various production equipment locations to a single batching vessel, accurately, reliably, each and every time. Advanced weighing technology along with integrated process controls combine to enhance the versatility and scalability of process weighing requirements.

How it works

An integrated weigh controller with multi-speed outputs is wired to a variable frequency drive for complete control over bulk material weighing. An operator selects a recipe, initializes the batch start sequence and the weigh controller takes over.

One material at a time will be weighed to its predetermined set point and then the controller will index to the next material and so on until the last ingredient is weighed. Upon completion of the weighing cycle, the weigh controller initiates the dump sequence. This will actuate a valve and allow the contents of the scale to be emptied and the valve closed, completing the batching operation.

Advantages

- Single or multiple ingredient(s) recipe storage

- Virtually eliminates over or under weighments due to operator error

- Reduces costs by reallocating workforce resources

Features

- Full numeric keypad for digital tare and data entry

- Large backlit graphical display

- User programmable soft keys

- Addition of a single or multiple material(s) using 2-speed weigh-in procedure

- Simplified material setup

Typical System Drawing

Detail of batch weigh hopper with load cells & pneumatic discharge valve

Get Started building your custom conveyor system.

Work directly with an experienced engineer who understands how to convey powders and bulk solid materials so you get the perfect solution for your process.