AFC Custom Solutions

Our engineering team offers unmatched skill and experience in devising novel solutions for tough powder and bulk solids handling problems.

AFC engineers custom design screw conveyors, bulk bag unloaders, bag fillers, and other bulk material handling equipment to solve difficult challenges in powder and bulk solids transfer. When you’re faced with a complex, confounding, or even a dangerously combustible dry processing situation, talk to our engineering team.

We’ve worked with hundreds upon hundreds of different materials and ingredients in a vast range of grades, particle sizes, shapes, bulk densities, and moisture levels for installation in hazardous and non-hazardous environments all over the world.

Our latest Custom Projects

Uncle Harry’s Natural Products called looking for a truly dust-free way to unload bulk bags of bentonite clay and transfer the fine powder into pails for production without leaving staff and building covered in clay dust. We understood exactly what the owner meant when he said he needed, “truly dust-free” and we designed and built a “truly dust-free” powder handling system. It integrates a custom bulk bag unloader with our AFC Spiralfeeder screw conveyor, all sealed from start to finish.

A major supermarket chain called us when they switched flour grades to reduce bakery costs and the new grade would not cooperate with the existing conveying system. With a sample of the alternative flour provided, we conducted a series of tests in our New Jersey test laboratory to assess its behavior and flowability. Then, we designed a conveying system to overcome the new flour’s penchant for caking, packing, and sticking:

- Hopper with vibrator – promotes consistent flow without sticking to walls

- Custom agitator – consistently feeds the flour to the screw

- Dust control cover – keeps the flour inside the conveying system

- Proprietary screw design – gently transfers the flour without clogging or degradation

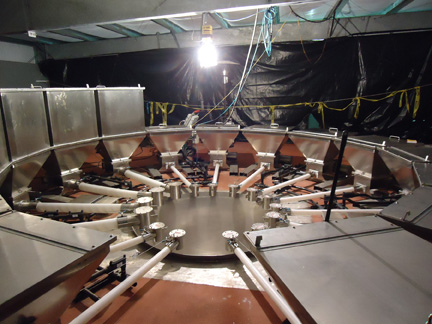

A specialty chemical company was struggling to transfer and accurately dose 15 different materials stored in 15 different locations into one reactor at the same time.

We devised a custom solution to automatically transfer each material from a storage hopper then weigh the preset amount, and precisely dose that amount into the reactor. This solution features 15 of our Batch-Weigh systems, custom-configured to automatically transfer, weigh, and dispense each material into the same discharge location. Over and under weighments due to human error were eliminated and product quality and consistency improved dramatically.