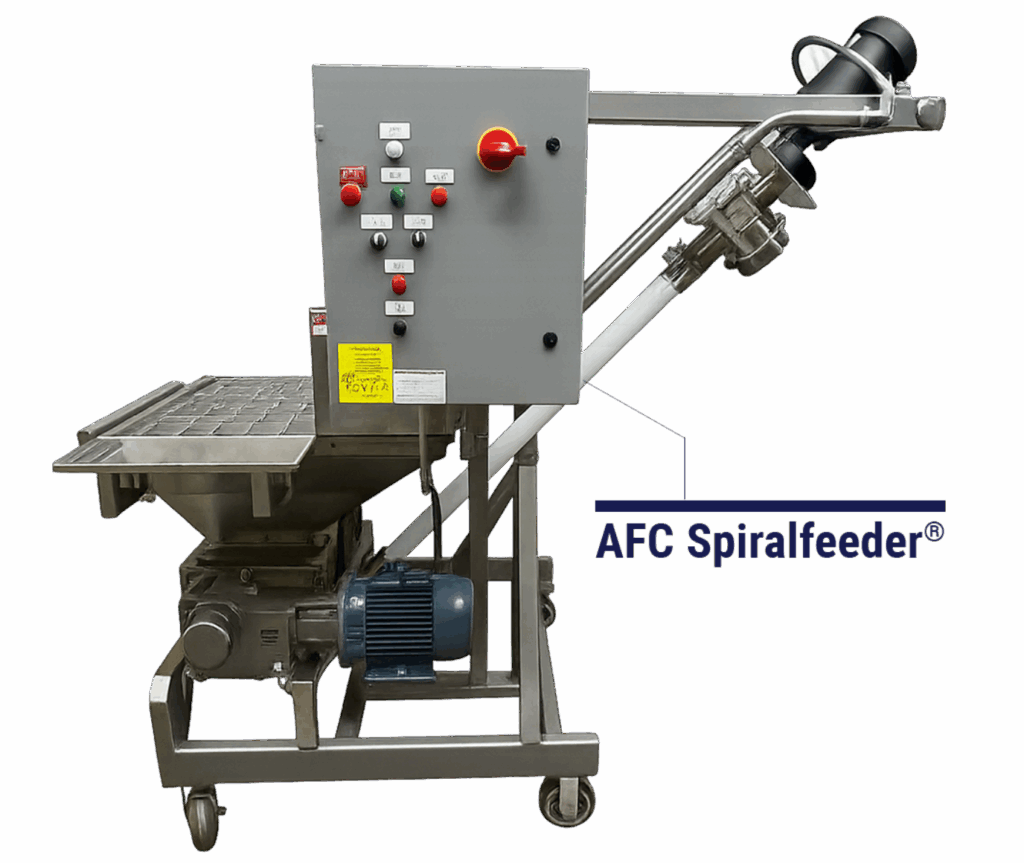

AFC Spiralfeeder® Screw Conveyor System

Meet the most versatile, customized conveying solution for moving powders and bulk materials.

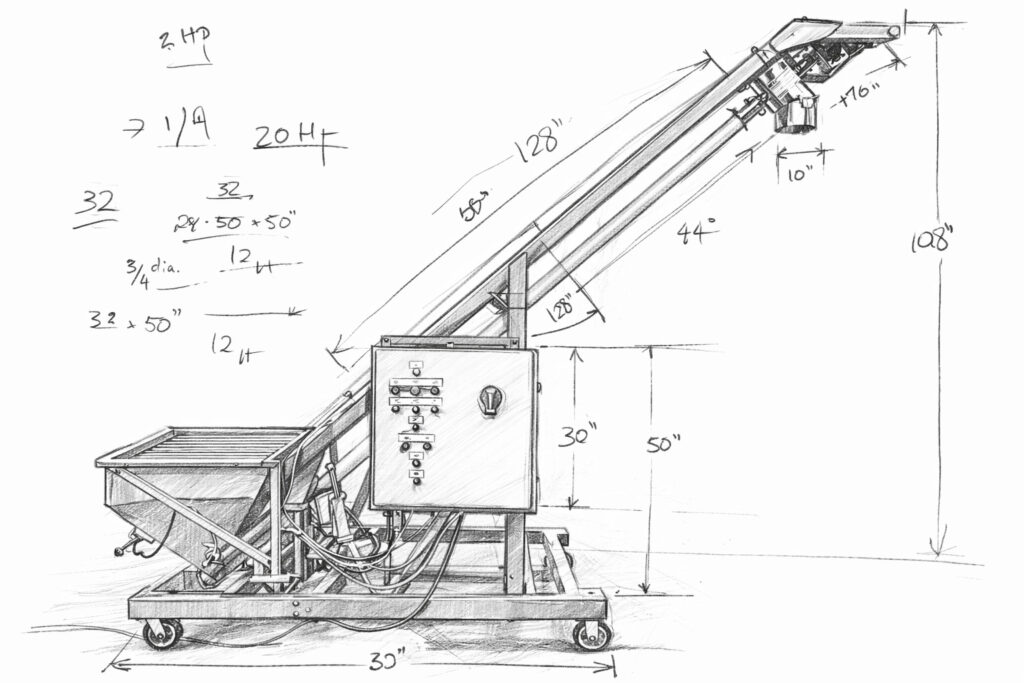

The AFC Spiralfeeder screw conveyor is designed and manufactured as a complete bulk material transfer system tailored to the goals and requirements of each installation. Choose this conveying approach when you need high throughputs, quick changeovers, dust-free conveying, and consistent, dependable, automated operation – even with caking, sticky, and ultra-fine materials. Work directly with a highly skilled engineer every step of the way from concept design to production, free testing – and follow-though.

How the AFC Spiralfeeder Conveying System Works

What Is It

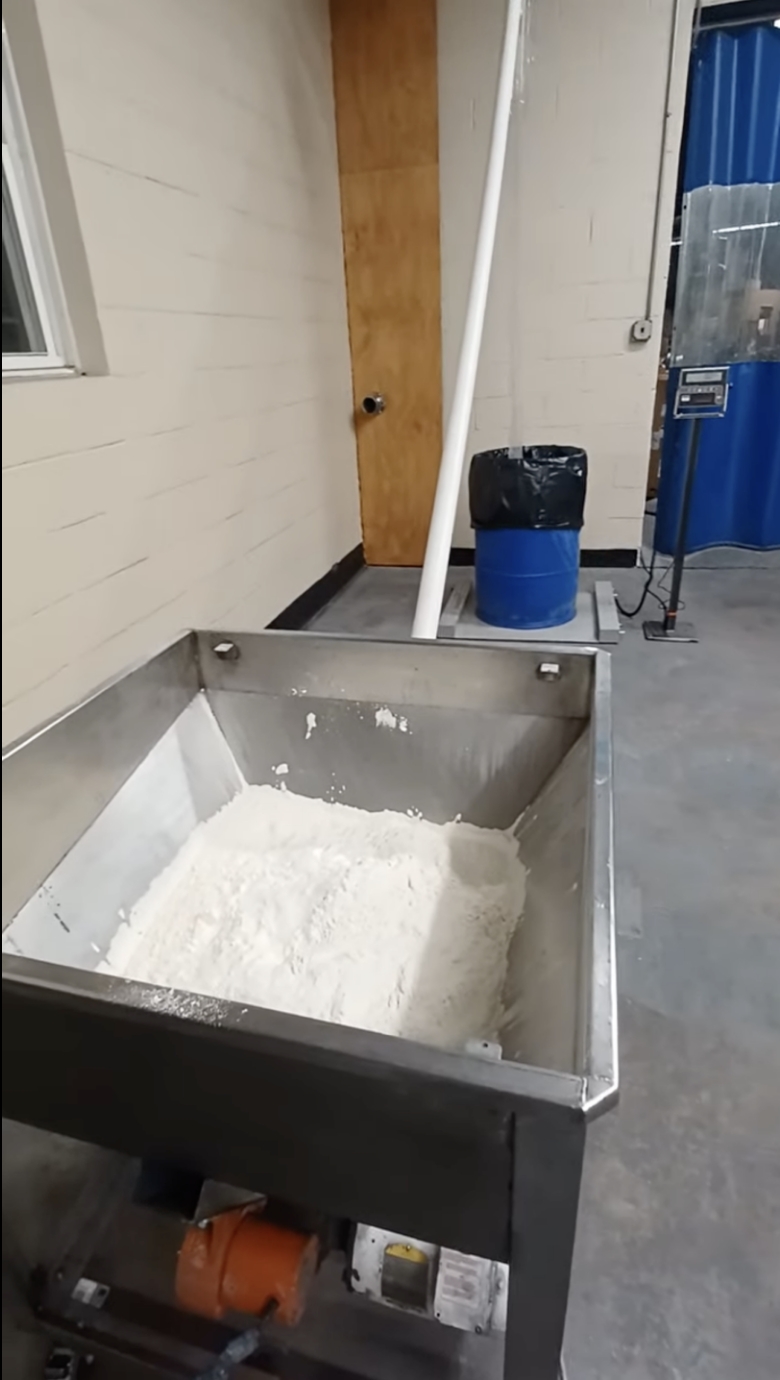

The AFC Spiralfeeder automatically transfers dry powders, granules, mixtures, blends, crystals, pellets, flakes and a wide range of other bulk materials from a hopper at floor level up to discharge via a rotating screw enclosed within a UHMW polyethylene outer tube. It’s often specified for conveying bulk solids into overhead surge hoppers, for filling bulk bags, and loading tanks, vessels, mixers and bulk containers. The AFC Spiralfeeder operates anywhere materials and ingredients need to be transferred from one processing point to another efficiently, safely, quietly and dust-free, even in hazardous environments.

How It Works

At the press of a button on the control panel, the steel screw begins rotating concentrically inside the stationary outer tube at a preset rate. This draws the material down from the integrated hopper and gently transfers it up to the discharge in seconds. Both the pitch of the screw flight design and rpm create a positive directional displacement of the bulk material within the outer tube. The material moves consistently from point of entry (inlet) to point of discharge (outlet) sealed in a first in – first out process without exposing the material to the plant environment to guard against contamination and without exposing workers to the material. This enclosed screw auger approach excels in transferring bulk materials up steep inclines and vertical runs that render belt conveyors impractical.

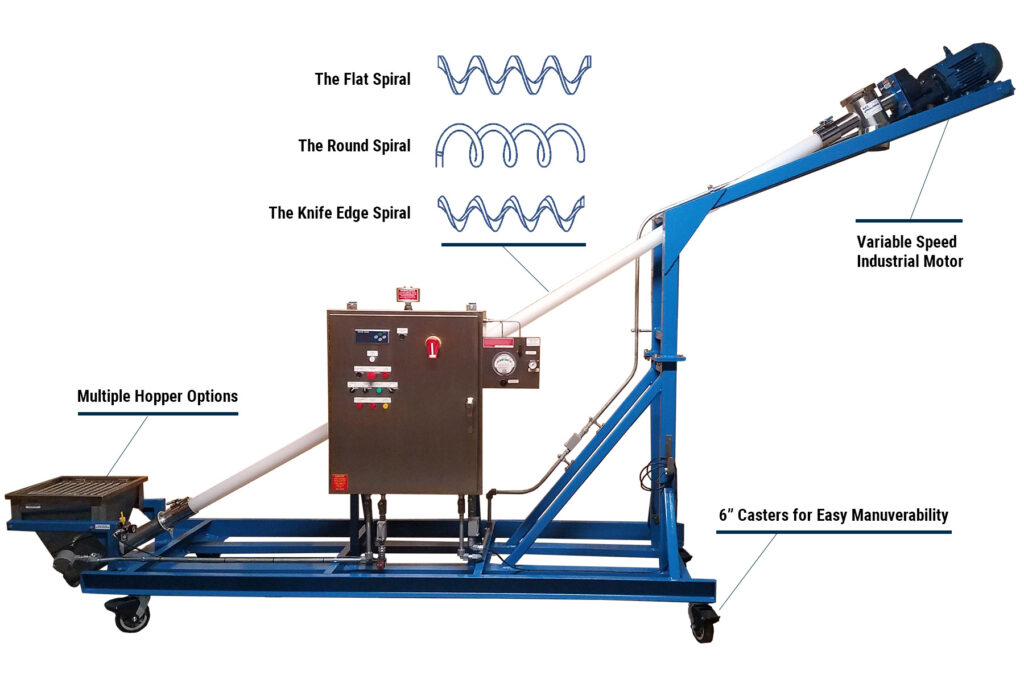

Customized Conveying Screws

AFC specifies different conveying screws based on the properties of the material to be transferred. The standard round spiral, flat spiral, and knife-edge spiral screws accommodate nearly every type of bulk material whether free-flowing or non-free-flowing, smearing, caking, bridging, or packing. These screws are interchangeable and may be quickly swapped out for transferring different materials on the same, compact conveying system.

If material testing and/or our engineering experience determine another type of screw configuration would provide even greater efficiency then AFC engineers custom design and manufacture the exact screw for the given material and process.

AFC also specifies custom hoppers to suit the material flow characteristics, throughput targets, and other requirements. Custom agitators, vibrators, air diffusers, dust control covers, and a diverse array of accessories are available to ensure smooth, non-stop powder flow and reliable, automatic conveying.

Key AFC Screw Conveyor Advantages

- Low Cost

- Low Maintenance

- Only (1) Moving Part

- Easily Installed

- Easily Cleaned

- Dust-Tight

- Quiet

- Rugged Construction

- Quick Disassembly

- No Compressed Air

- No Vacuum

- No Internal Bearings

- No lubricants

- Easy to use

Quality Construction, Expert Engineering as Standard

- Choice of carbon steel or stainless steel screw with industrial coatings or sanitary finish

- F.D.A./U.S.D.A. – approved materials, abrasion resistant UHMW polyethylene outer tubes

- Rugged steel frame manufactured on-site in New Jersey

- Electrical control wiring enclosed inside corrosion-resistant, aluminum conduit

- Wide variety of factory engineered/pre-wired custom controls to suit your exact process requirements

- Powerful variable-speed industrial motor

- Integrates with Programmable Logic Controllers (PLC), and Internet of Things (IoT) networks

SPIRAL TYPES

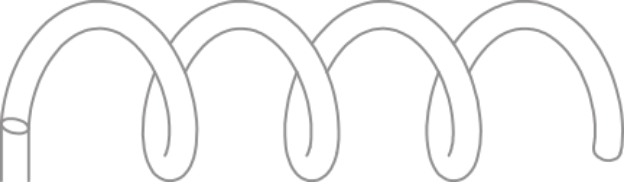

The Round Spiral

Provides maximum flexibility and strength, due to the round cross sectional design.

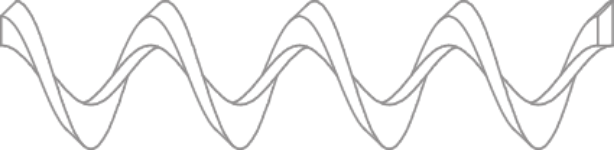

The Flat Spiral

Provides greater conveying performance at a reduced rpm.

The Knife Edge Spiral

Proprietary AFC advance handles difficult materials that cake, pack or smear to upgrade most traditional mechanical conveyors.

FROM THE TEST LAB

Featured Spiralfeeder Products

AFC Tiltable Spiralfeeder

This award-winning, portable screw conveyor makes moving the entire unit from one area in the plant to another area fast, safe, and easy. At the press of a button, the entire unit automatically tilts down to lower the height enough to fit through standard-height doorways. It automatically locks in place for secure transport on an integrated, mobile platform. Once rolled to another processing line or area, a press of a button automatically raises the conveying system for return to service.

- No tools or disassembly needed

- No forklift needed

- One tiltable conveyor can serve multiple processes

AFC Spiralfeeder FTH 25

This compact, portable powder conveyor features a complete AFC Spiralfeeder conveying system plus the integrated hopper sports designed-in fork pockets for safe, easy transport by forklift or pallet jack. This design offers a convenient, economical way to move the conveyor around the plant. It is typically used to empty bags of material into the hopper then drive the unit to a mixer, tank, or filling line for loading.

AFC Spiralfeeder Push Unit

This conveyor model sets the drive mechanism at floor level by the hopper rather than up at the discharge. This low profile configuration is especially compact and fits neatly into many tight spaces that would rule out longer, taller conveying systems. Access to the electric motor and gearbox at floor level also eliminates the need for ladders or other lifting devices when it’s time for maintenance. This Push Unit virtually eliminates the risk of slips, trips, and falls involving heights.

In addition to providing easy access to the drive system, the Push Unit also makes it easy to access the bottom of the hopper and tube inlet so emptying any residual material between batches is easy – and no tools needed.

To empty the powder transfer system, an operator simply shuts off the power, removes a tri-clover fitting (optional), places a collection bin or bag underneath the conveying tube, then turns the screw conveyor on in reverse. Material entrained inside empties automatically. It can be put back in storage or reused with no mess. For a complete cleaning when changing products, the solid, outer metal tube may be removed to access the conveying screw, and both may be cleaned along with the hopper grate and interior by one worker in minutes.

AFC Spiralfeeder XP

When hazardous process conditions demand extreme, explosion-proof protection, the AFC Spiralfeeder XP shines. This model features an explosion-proof, NEMA 4 Bebco purge control panel enclosure in stainless steel and upgraded hazardous location motor with companion electrical components that meet National Electrical Code standards for transferring hazardous materials. An optional purge unit maintains constant pressure without permitting contact with the outside atmosphere.

It’s often specified for food, chemical, pharmaceutical and other bulk solids processors concerned with transferring combustible dust, ignitable powders, low Minimum Ignition Energy (MIE) materials. The Spiralfeeder XP is suitable for safe bulk material transfer in Class II, Division II locations and may be custom-engineered with the properly rated motor, control panel, and enclosure for other locations. Custom XP models complying with NFPA codes and standards and/or ATEX guidelines are available.

We Know, One Size Does NOT Fit All

When you’re faced with a complex, confounding, or even a dangerously combustible dry processing situation, talk to our engineering team. We’ve worked with hundreds upon hundreds of different materials and ingredients in a vast range of grades, particle sizes, shapes, bulk densities, and moisture levels for installation in hazardous and non-hazardous environments all over the world.