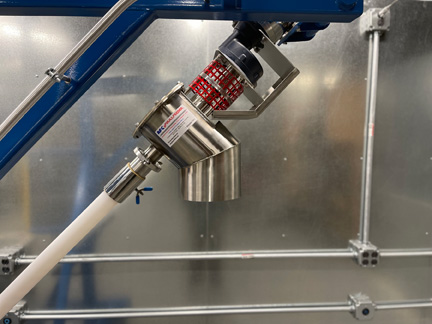

Novel Design By AFC Eliminates Lip Seal and Its Crevices

Clifton, NJ: Process equipment manufacturer Automated Flexible Conveyor, Clifton, NJ, (afcspiralfeeder.com) has introduced a conveyor discharge adapter. Offered as an option on its AFC SPIRALFEEDER(TM) flexible screw conveyors, the new discharge adapter features a proprietary design with a tri-clover sanitary fitting that maintains the position and stability of the tube enclosing the rotating screw conveyor while eliminating a traditional lip seal with its potential to capture and accumulate material. The risks of cross-contamination and bacterial growth are virtually eliminated and removal for cleaning is quick and easy.

Developed for a major snack chip manufacturer, the conveyor discharge head is suitable for food, nutrition, pharmaceutical, and other sanitary processes where FDA compliance is required and purity is paramount. The discharge adapter is manufactured in stainless steel with a choice of sealed connections for transfer to bulk bag fillers, hoppers, dryers, and other downstream equipment.

The sanitary conveyors with the new discharge are designed and manufactured at the company’s New Jersey facility and may be tested in the on-site test laboratory. The discharge adapter may be retrofit onto flexible screw conveyors in the field from any manufacturer.

For more information, contact Automated Flexible Conveyor, Inc., 55 Walman Ave., Clifton, NJ 07011; 800-694-7271, [email protected]; AFCSpiralFeeder.com.

# # #